- Gavin.chen@newstep-hk.com

- +86 18588596059

Analysis on the current market situation and development tre

China Business Information Network News: In the downstream application industry of molds, the automobile manufacturing industry uses a large amount of molds. 95% of the parts in automobile production need to be molded by molds. The main types of molds used include injection molds, stamping molds, forging molds, casting molds, etc.

China's automobile production and sales volume has ranked first in the world for 11 consecutive years. China's market share in the global automobile manufacturing industry has increased from 13.78% in 2008 to 28.23% in 2019. Affected by the epidemic of Neocoronal Pneumonia, China's automobile production will be affected to some extent from 2019 to 2020. The data shows that in 2019, China's automobile output was 25.53 million, down 8% year on year. From January to October 2020, China's automobile output was 18.98 million. The continuous development of the automobile industry has promoted the growth of the demand of the automobile die market.

Data source: sorted by China Commercial Industry Research Institute

2、 Development Trend of China's Mold Manufacturing Industry

(1) The market share of leading enterprises has increased, and the industry concentration has gradually increased

At present, the mold manufacturing industry is dominated by small and medium-sized enterprises, with a large number, but the industry concentration is low. With the continuous growth of demand for high-end downstream applications such as automobile lightweight, consumer electronics, rail transit, etc., leading enterprises in the industry have increased investment in research and development while deepening their existing customers, accelerated the automation upgrade of production lines, improved the level of new product development, and constantly enhanced one-stop supporting services for multiple specifications and full production lines, thus occupying new market shares, while the technology level is low and the technology development ability is weak Small enterprises with poor service capacity will be phased out gradually, and market resources will be gradually concentrated to the advantageous enterprises in the industry.

(2) The domestic low-end market is relatively saturated, and the pace of localization of high-end market is accelerated

Compared with international leading enterprises, there are a large number of domestic mold manufacturing enterprises, but most of them are limited in equipment level and R&D investment, mainly producing low-end products, and relatively single varieties, which are difficult to meet the needs of the upgrading downstream market. In recent years, some domestic leading mold manufacturers, by introducing foreign advanced production equipment and technology, at the same time, strengthen independent technology research and development and production process innovation, improve the automation level of the production line, improve product accuracy and stability, compete comprehensively with international manufacturers in the middle and high-end markets, and constantly realize the import substitution of middle and high-end products.

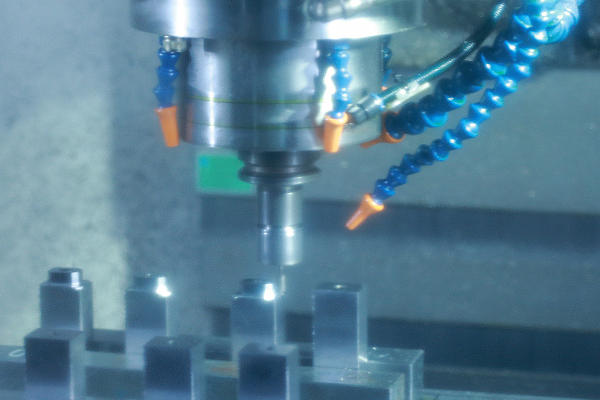

(3) Manufacturing is developing towards automation and intelligence, and production efficiency is greatly improved

With the deep application of CAD/CAE/CAM integration technology, 3D design technology and other information management technologies in the mechanical manufacturing industry and the development of the Internet of Things technology, the mold manufacturing industry will improve the ability of new technology integration and software and hardware integration in the production and design process in the future, promote the development of production and manufacturing to the direction of automation and intelligence, so as to improve the mold processing efficiency and manufacturing accuracy. On the basis of the existing technical level and manufacturing capability, the mold manufacturing industry is gradually realizing the upgrading of efficiency, automation and intelligence through the integrated application of communication technology, big data and Internet of Things technology, and comprehensively improving the product design capability and production process control capability.

(4) Responding to market demands quickly and improving customized R&D and design capabilities have become an important factor in competition

Mold manufacturing products are usually customized for the actual needs of customers. In recent years, with the expansion of downstream applications such as photovoltaic, wind power, automotive lightweight, consumer electronics, and so on, the speed of product updating has been accelerating. As an upstream field, the mold manufacturing industry should have a deep understanding of product characteristics and customer needs, participate in customer initial research and development, shorten the research and development cycle, speed up production and service response, and improve product quality stability. The ability to carry out synchronous R&D, design and manufacturing for customers and market demands has gradually become an important indicator to measure the market competitiveness of enterprises.

For more information, please refer to the Research Report on Market Prospects and Investment Opportunities of China's Mold Manufacturing Industry issued by China Commercial Industry Research Institute. Meanwhile, China Commercial Industry Research Institute also provides industrial big data, industrial intelligence, industrial research reports, industrial planning, park planning, the 14th Five Year Plan, industrial investment promotion and other services.

Copyright © 2002-2030 cnnewstep.com 东莞市新达科技有限公司 版权所有 粤ICP备2022094386号