- Gavin.chen@newstep-hk.com

- +86 18588596059

Advantages and disadvantages of driving the development of p

Due to the huge market scale and large number of enterprises in China's mold industry and plastic products industry, the industry market concentration is low. Raw materials required for the production of precision injection molds include mold steel, mold base, etc.

A series of relevant policies and regulations issued by the state constantly guide the mold market towards high-end: the High end Intelligent Remanufacturing Action Plan (2018-2020) policy promotes China's large-scale manufacturing enterprises to develop towards more sophisticated parts; The Investment Guide for Technological Transformation and Upgrading of Industrial Enterprises (2019 Edition), the Guiding Catalogue for Industrial Restructuring (2019 Edition) and other policies clearly propose to encourage enterprises to invest in the design and manufacturing of precision molds.

The Outline of the Fourteenth Five Year Plan for the Development of the Mold Industry clearly proposes to accelerate the steady development of China's mold industry towards the "three highs" of high level, high quality and high efficiency of mold products, and the "three modernizations" of systematization of mold industry manufacturing, customization of services and replacement of processes. The Guiding Opinions on the Fourteenth Five Year Plan for the Development of Plastic Processing Industry pointed out that we should speed up the promotion of technological transformation and promote the plastic processing industry to move towards the middle and high-end. By 2025, the main products and accessories of the plastic processing industry can meet the needs of national economic and social development, especially in high-end areas, and some products and technologies will reach the world's leading level. With the improvement of people's life and consumption level, the trend of high-end consumption of injection molding products is increasingly obvious; Compared with low-grade injection products, medium and high-end injection products pay more attention to material, workmanship, shape design and performance, which also puts forward higher requirements for mold structure, process and precision, as well as the material of injection products. Under the guidance of such policies, excellent enterprises in the industry reduce product homogeneity competition by strengthening independent R&D investment and strengthening core competitiveness.

1. Favorable factors

(1) Strong support of national policies

Manufacturing industry is the pillar industry of China's national economy. As an important supporting industry of modern precision manufacturing, the development of mold industry and plastic products industry has always been valued by the state. In recent years, the central and local governments have successively issued a series of industrial policies and medium - and long-term development plans to support the mold industry and plastic products industry to become bigger and stronger. In recent years, the country has issued a series of relevant policies and regulations to guide the mold and plastic products industry to move towards high-end: the High end Intelligent Remanufacturing Action Plan (2018-2020) policy has promoted China's large-scale manufacturing enterprises to develop towards more sophisticated parts; The Investment Guide for Technological Transformation and Upgrading of Industrial Enterprises (2019 Edition), the Guiding Catalogue for Industrial Restructuring (2019 Edition) and other policies clearly propose to encourage enterprises to invest in the design and manufacturing of precision molds for non-metallic products. "Functionalization, lightweight, precision, ecology and intelligence" in the "Fourteenth Five Year Plan" Scientific and Technological Innovation Guidance for Plastic Processing Industry is the development direction of technical innovation in the plastic processing industry; "Injection molding products for medical, electronic, household appliances, transportation and other micro nano and high-precision products, and injection molding products for plastic wood products with complex shapes" were included in the development direction of key products during the "Fourteenth Five Year Plan" period.

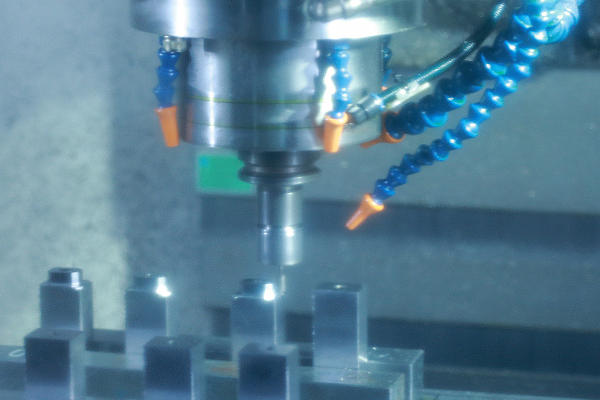

(2) Continuous progress of industry technology

After years of independent accumulation, introduction, absorption and re innovation, China's mold industry has reserved a certain technical foundation. At present, the number of precision, large and composite mold products in the industry has increased significantly, and the main indicators of some leading enterprises' products have reached the international first-class level. Key enterprises in the mold industry have also gradually implemented advanced technologies and processes such as high-speed processing, concurrent engineering, reverse engineering, virtual manufacturing, non drawing production and standardized production, which has established a good demonstration effect for the development of the industry.

(3) The focus of international host and supporting industries continues to shift to China

The development of mold industry is closely related to its downstream industries. In recent years, the trend of industrial transfer, supply chain globalization, and the rapid development of downstream industries such as domestic automobile and electronic products have provided a good external environment for the development of mold industry, one of the basic industries of manufacturing industry. For domestic mold enterprises, on the one hand, it is a good opportunity to enter the international market and become a global mold supplier, which can obtain more market opportunities; On the other hand, the shift of the global mold industry focus to China will help Chinese enterprises digest and absorb foreign advanced technologies and products, thus narrowing the gap with the advanced level.

(4) Market demand expansion

With the growing national income, consumers' demand for products has gradually expanded in terms of variety and quantity, and their requirements for quality have gradually increased. Strong demand in household appliances, daily necessities, consumer electronics and other industries has provided conditions for capacity digestion of relevant manufacturing industries.

2. Unfavorable factors of industry development

(1) The scale of enterprises is generally small

The low universality of mold products and the obvious characteristics of specialization and differentiation have resulted in the small average scale of China's mold enterprises, which are at a disadvantage in dealing with fluctuations in raw material prices, customer changes, and participation in international market competition. In order to become bigger and stronger, China's mold industry not only needs to make breakthroughs in the development of medium and high-end molds to replace imported products, but also requires small and medium-sized mold enterprises to provide customers with supporting services such as injection molding product processing on the basis of focusing on mold development, so as to achieve diversified income sources and large-scale operation of enterprises.

(2) Advanced technology lags behind overseas, and high-end production equipment depends on imports

China's mold industry has made great progress in product precision, life span and complexity, but there is a big gap between high-end technology and comprehensive R&D and production level of enterprises and overseas advanced enterprises, which has a certain impact on the precision, production efficiency and profitability of injection molding products. In addition, the development level of domestic plastic products enterprises is uneven, and there is a lack of large and advanced enterprises. Most of them are small and medium-sized enterprises. The overall product technology level is at a low level, and there is a certain gap with the advanced level abroad.

Moulds are the basis of all injection molding products. The quality, accuracy, service life of molds, and the precision and production efficiency of injection molding products have high requirements on production equipment. Without high-end advanced equipment, high-precision molds and high-quality injection molding products cannot be produced. After many years of technical transformation in China's mechanical processing industry, the technology of process equipment has been greatly improved. The domestic machine tools and other tool industries have been able to provide processing equipment with a certain precision, but high-end equipment with high precision, stability, reliability and efficiency still needs to be imported from abroad.

(3) The industrial chain is not perfect

In China, the coordinated development of all links of the industry chain with mold as the core is not enough, especially the development of mold materials lags behind. Mold materials have a great impact on mold quality. For a long time, domestic mold materials cannot meet the needs of the industry in terms of variety, quality or quantity. The materials of high-end molds and export molds almost all rely on imports. In addition, various upstream equipment (machine tools, tool clamps, measuring tools, testing and heat treatment equipment, etc.) and production means (software, auxiliary materials, consumable parts, etc.), as well as forming materials (various plastics, rubber, plates, metal and non-metal and composite materials, etc.) and forming equipment (rubber and plastic forming equipment, stamping equipment, casting and forging equipment, etc.) rely heavily on imports, which limits the rapid development of the mold industry.

(4) Weak financing capacity of enterprises

At present, the industry is dominated by small and medium-sized enterprises, and the scale, credit rating and other restrictions determine that the available financial support is very limited. Although financial institutions have formulated loan policies for SMEs, it is difficult to fundamentally solve the problems of difficult loans and financing, which has become another bottleneck for the rapid development of SMEs in the industry.

3. Barriers to entry

(1) Technical and experience barriers

Technical level and professional production experience are the core competitiveness of the industry. From the design and development of precision injection mold, scientific mold testing to injection molding, assembly of components and surface treatment, the processes must be precisely coordinated and connected. Therefore, enterprises need to have strong mold design and development capabilities, injection molding processing technology, and higher quality control and production management levels. This not only requires enterprises to invest in long-term technology research and development, but also requires enterprises to accumulate valuable manufacturing and management experience in long-term practice. In recent years, the upgrading of downstream products in the plastic products industry has become faster and faster. Plastic products enterprises need to design and develop corresponding molds in strict accordance with the time requirements of downstream customers, and have the ability of efficient and mass injection molding. In a short period of time, we will develop molds that meet the requirements of appearance, precision, quality, service life, etc., and deliver a large number of injection molding parts in a short period of time, which puts forward quite high requirements for the R&D and design capabilities, mold manufacturing capabilities, and batch molding manufacturing capabilities of enterprises. In addition, the high requirements of downstream customers for products also urge plastic products enterprises to constantly introduce new processes and technologies, constantly improve the automation level and optimize the product structure. It is difficult for new enterprises to break the above technical and experience barriers in a short time.

(2) Qualification barriers to entering the supply chain of well-known enterprises

Mold and injection molding products are the basic components of downstream products. Stable product quality, accurate specifications and dimensions, and on-time delivery time are of great significance to complete the complete end product. To become a supplier of a world-famous enterprise, in addition to meeting the industry standards, it is necessary to pass the strict qualification review of suppliers by customers. Generally, the identification of suppliers takes a long time. Downstream customers conduct a comprehensive and comprehensive investigation on the supplier's technical level, production conditions and production equipment, quality control, financial situation, enterprise reputation and other aspects. They put forward strict requirements in all aspects of production. After layers of review and inspection, they can pass the preliminary qualification identification. And they can formally enter the supplier directory only after multiple batches of small supplies reach a stable quality state. Once the enterprise has obtained the supplier qualification of a world-class enterprise, it will be incorporated into its global supply chain system and can receive its purchase order. Therefore, strict supplier qualification identification has formed a qualification barrier for entering the supply chain of global well-known enterprises.

(3) Financial barriers

Plastic products industry is a capital intensive industry. The manufacturing cycle of precision injection mold is long and the value is high. High quality mold steel, mold base, mold accessories and other raw materials need to be used. From the purchase of raw materials to the delivery of products, a large amount of working capital needs to be occupied; The large scale output of injection molding products and the large quantity of raw materials purchased increase the demand for working capital; In order to maintain market competitiveness and quality stability, enterprises need to invest a lot of money in plant construction, procurement of production equipment and R&D instruments, technology research and development, introduction of professional technicians and management teams, etc. The above multiple factors have caused high capital barriers in the industry where the enterprise is located.

(4) Scale production capacity barrier

The plastic products industry has high requirements for equipment investment and strict requirements for production process and product quality. Injection molding products for consumer electronics and auto parts have high requirements on the timeliness of supply and capacity scale of manufacturers to meet their large-scale order demand. Only enterprises that have reached a certain production scale can obtain orders. Therefore, only enterprises with sufficient equipment scale and a certain number of workshops, technicians and skilled workers can provide sufficient production capacity and enter into higher level competition.

(5) Brand barrier

The brand comprehensively reflects the R&D design, product quality, operation management and after-sales service level of an enterprise. The establishment and formation of a well-known brand requires a lot of investment, but also requires long-term reputation accumulation and reliability verification. As the basis of precision manufacturing, mold is directly related to the production quality and product performance of related plastic products. As plastic products are produced in large quantities on the basis of molds, once problems occur in the mold, a large number of defective products will be caused, which will directly affect the production and product quality of downstream manufacturers, causing huge losses. Therefore, the reputation and brand of mold enterprises are very important. Having a high brand guarantee is an important factor for customers to choose their supply chain enterprises. Famous customers in automobile, electronic products and other industries tend to maintain long-term cooperation with suppliers with high brand awareness. The precision injection mold industry has entered the era of brand competition, which has also formed a high barrier for new entrants.

Copyright © 2002-2030 cnnewstep.com 东莞市新达科技有限公司 版权所有 粤ICP备2022094386号