- Gavin.chen@newstep-hk.com

- +86 18588596059

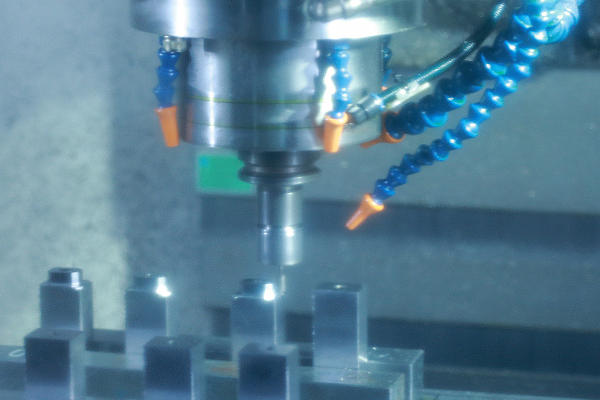

The prospect of precision die industry is broad

The mold industry has a broad prospect, and the precision mold market is in short supply. However, the proportion of high, middle and low-end products produced in China's mold industry is extremely unbalanced, which is very detrimental to the development of China's mold industry. It is urgent to speed up the structural adjustment, develop the high-end market and keep pace with the international market.

Accelerate structural adjustment

Compared with the previous years, the level of mold technology in China has been greatly improved, but the proportion of high, middle and low end production in the domestic mold industry is extremely unbalanced, which is very unfavorable to the development of the mold industry in China. Although in recent years, the structure and system of China's mold industry have made great changes, mainly as follows: medium and high-grade mold, large, precise, complex, and long life. However, due to the excessive demand for medium and low grade molds in China, the self matching rate of medium and high grade molds is less than 60%. It is not difficult to see that it is unreasonable.

They are mainly manifested in the following aspects: First, mold steel and other constraints; 2、 The standardization level needs to be improved; 3、 High end mold talents are in urgent need of cultivation; 4、 Speed up the adjustment of mold product structure; 5、 Increase investment to strengthen innovation capability; 6、 Promote the joint reorganization among mold enterprises; 7、 Overseas market development needs to be deepened.

Improve the technological level

As the key and core molds of downstream industries, especially the automobile industry, are highly dependent on imports, a series of key and core injection molding products required by related host products are also mainly provided by these internationally renowned mold enterprises.

In recent years, the enterprises in the cabinet have continuously improved the mold process technology and products. As a result, some plastic molds or injection molded parts have begun to circulate internationally and have successfully entered the supply chain system of some high-end industries, replacing some imported products and getting rid of their dependence on them. However, it is undeniable that only a few of them are in the international high-end market.

According to the 12th Five Year Plan, China's mold industry will focus on breaking through the design of large and precise plastic molds, such as automotive plastic molds, marine plastic molds, etc. Only by constantly following up these new advanced technologies and products, can we not be eliminated by the times. With the improvement of technology level and gradual increase of product level in China's mold industry, the supply chain system of some international host industries is now further inclined to domestic enterprises, which will be an opportunity and challenge. It is understood that by 2015, the independent matching rate of molds required by the Chinese market will reach more than 85%, of which the independent matching rate of high-end molds will significantly increase.

Some experts pointed out that in the future, in addition to continuing to improve the production capacity, China's mold industry should focus on internal structural adjustment and technical development. It is mainly about the adjustment of enterprise structure towards specialization, the development of product structure towards medium and high-end molds, the improvement of import and export structure, the analysis of the forming and structure improvement of the middle and high-end automobile panel dies, the application of multi-function composite dies and composite processing and laser technology in mold design and manufacturing, the development of high-speed cutting, ultra precision machining and polishing technology, and information technology.

Copyright © 2002-2030 cnnewstep.com 东莞市新达科技有限公司 版权所有 粤ICP备2022094386号