- Gavin.chen@newstep-hk.com

- +86 18588596059

Dong Mingzhu leads Gree's sword finger mold industry! Not on

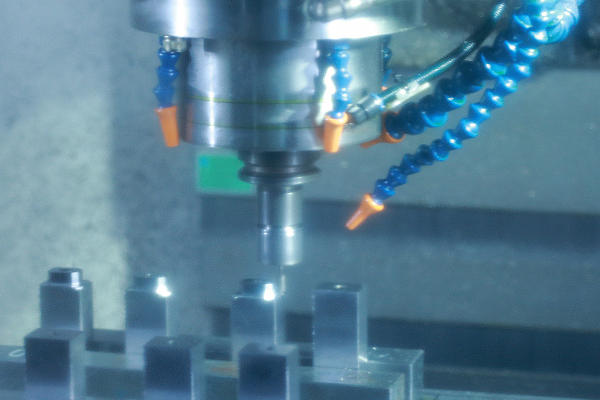

As the core of modern industry, mold has always been known as the "mother of industry". In electronics, automobiles, motors, instruments, household appliances, communications and other products, 60% - 80% of parts rely on mold forming. In order to realize the transformation and upgrading of China's manufacturing industry and improve product quality, the development of precision mold industry is the top priority.

Today, let's talk about Gree's "precision mold".

"What is a mold"

Strictly speaking, it refers to: in industrial production, metal or non-metallic materials are made into parts or products of required shape by various presses and special tools installed on the presses through pressure.

To put it simply: make products into tools of different shapes and sizes. For example: flower pots poured with cement, letters engraved on chocolate, and all car covers... all of these require molds.

Mold classification: according to the different materials, it can be divided into metal mold, plastic mold and other special molds. Among them, hardware molds can be divided into stamping dies, forging dies, extrusion dies, and extrusion dies

"Mold is a major breakthrough of Gree's independent innovation"

In recent years, domestic home appliance giants are transforming from low-end factories to high-end manufacturing. Gree is a typical representative of the transformation and upgrading of China's manufacturing industry.

In 2013, Gree entered the precision mold industry. In 2016, Zhuhai Gree Precision Mold Co., Ltd. was established. In addition to taking Zhuhai as the core, Gree also laid out mold intelligent manufacturing bases in Wuhan, Hangzhou and other places.

Gree vigorously develops precision molds, which not only provides a stage for its core technology and innovative process level, but also provides services for customers in BMW, Honda, Amazon and many other fields. Gree precision molds are developing rapidly in home appliances, automobiles, 3C and other fields, among which high impact molds can be punched up to 380 times per minute, catching up with leading enterprises at home and abroad.

Most domestic air conditioning enterprises do not have the ability to open their own molds, which leads to serious homogeneity in the appearance of domestic air conditioning products. At the same time, the domestic mold industry has a relatively small market scale and a large degree of technical completion. Many enterprises are unwilling to invest in this field, so China's mold industry is highly dependent on foreign countries.

Dong Mingzhu has a personal feeling about these problems. When producing air conditioners, she found that no equipment enterprise in China could meet the company's requirements. "It is impossible to produce high-end equipment in China. As long as high-end equipment is imported, it is terrible."

Therefore, in terms of R&D investment, Dong Mingzhu said: "Sometimes it takes millions of yuan to research and develop a project and buy one thing. Everyone who comes to me for signature trembles, but as long as it is used for R&D, I will not disapprove it."

Since Gree has made great efforts to develop precision molds, most of the production equipment used in the production workshop of Gree Electric has been developed and produced by Gree itself. In addition to the fact that the industrial automation production lines are all developed and produced by ourselves, what is more important is that Gree has been able to gradually replace itself by relying entirely on the high-precision and sophisticated molds imported from Germany and Japan.

Today, Gree has invested and built many mold bases, has more than 1200 CNC equipment, has independently developed more than 20 mold automation production lines, and has more than 2200 mold employees.

"Gree has found a correct development path, that is, it never makes fast money, but continues to devote itself to the manufacturing industry to create high-quality products that lead the world." Dong Mingzhu said.

In the current complex and changing economic environment, the rapid development of industries in various countries has attracted much attention. China's manufacturing industry is promoting the steady development of the national economy at a speed that we cannot wait for. Gree precision molds have become dazzling and dazzling under the tide of the times. Made in China is full of power and moving forward rapidly on the journey of building a manufacturing power.

Copyright © 2002-2030 cnnewstep.com 东莞市新达科技有限公司 版权所有 粤ICP备2022094386号